simple complexity

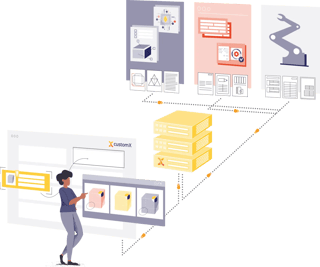

Complex and yet simple? With the customX software platform, even complex variant products can be mapped in a structured and simplified way - we call that: maximum digitalisation!

Maximum digitalisation with customX

But what exactly does that mean? Our mission is to make complex products configurable and to simplify the value-added processes behind them.

This requires solution-oriented ways of thinking and complex know-how so that we can prepare our customers for future-oriented ways of working on an individual basis.

In order to achieve this goal, all knowledge about the product is digitised in the rulebook. After a short basic training session, this can be done by every team member.

Regardless of whether it's parts lists, work plans or scaled production drawings - all documents are created fully automatically according to the zero-error strategy.

Digitise product knowledge

An unstructured exchange of information between the individual departments and insufficiently defined work processes are often the main reasons why companies lack efficiency in their day-to-day business. With customX, product knowledge for industry-specific variants is digitalised and work processes are automated.

With our team and software-based solutions, we help optimise your workflows and create clear interfaces between departments. Your product is described systematically, logically and CAD-independently without sacrificing variant diversity.

From marketing to engineering to the commissioning of the finished product, all departments benefit from customX. The departments have equal access to the product knowledge and thus experience maximum transparency.

The central application besides the rulebook is the web interface of the configuration: The installation of e.g. CAD software on all devices is no longer necessary. By bundling all systems, files are automatically generated for all departments without having to actively operate them. In addition, engineering processes are digitalised so that company-wide standards apply.

In this way, you secure all knowledge about your product digitally and centrally, instead of in the heads of your employees and in other such places.

For us, that is maximum digitalisation.

Why customX? Reasons for a...

Managing Director

The success of your company depends significantly on being able to efficiently satisfy individual customer needs. With the customX software platform, you will implement a well thought-through system that enables extensive automation of business processes. At the same time, with customX you no longer need to worry about the omnipresent shortage of skilled workers, especially in technical areas.

Head of Process

Silo thinking is a thing of the past - the configuration function of the customX software platform eliminates outmoded departmental thinking by automating the entire process from sales to production while keeping individual customer solutions at the forefront. Moreover, you do not need any external service providers for maintenance! This is because the software is designed for technical staff without programming skills.

Sales Manager

The market demands extremely short delivery times with unlimited individuality. Is that possible? Of course: the software platform customX does exactly that! You enter the requirements, present the customer’s individual product variant directly to them, and can quote an exact price straightaway, without having to clarify the technical feasibility and costs in other departments beforehand. This is how informed consulting works today!

What is your added value?

With customX, individual variants are just as easy and inexpensive as standard products. This is mass customisation like in the textbook!

customX puts your product in the centre - the entire structure is based on your product structure. customX opens up to communicate with other systems such as ERP or CAD and is not limited to any specific system.

A product-centric approach within the company enables a customer-oriented process externally.

What our customers have to say

customX is our knowledge database in which the complete product know-how is recorded. The easy retrieval of data makes maintenance and expansion of the system very simple.

Stephan Naetscher

Industrial Engineer - Operational Excellence, Trench Germany GmbH

customX drastically simplifies the work of the design engineers and also increases the efficiency of the entire process enormously. Our expectations have been far exceeded.

Chirstoph Lüning

Application Manager, Reflex Winkelmann GmbH

The configurator will make planning easier for our customers and also simplify in-house processes.

Michael Waldvogel

Product Manager, Hawa Sliding Solutions AG

I'm particularly impressed that you can build such powerful software with just a few parameters.

Marcel Cacek

Design Manager, FGS GmbH

Construction times for boxes configured with customX have decreased by more than 80 %.

Alois Mathis

CEO, cargopack tägi AG

Construction times for boxes configured with customX have decreased by more than 80 %.

David Dostmann

IT Manager, WätaS Wärmetauscher Sachsen GmbH

With customX we use a professional system which allows fast, complete and error-free configuration of variant.

Heiko Germershausen

Techniscal sales, Bals Elektrotechnik GmbH & Co. KG

With customX as a main block of our digitization strategy, both external and internal parties benefit from our accumulated, digitized product knowledge. Architects can configure their own variants at any time and download the BIM data directly, and customX creates all the important documents for our internal processes

Alexander Dück

Manager Parametric Product Configuration, JET Part of VELUX Commercial

An experienced designer does not need to think long about what can be manufactured and how. But when such an employee leaves the company, the knowledge is lost. Thanks to customX, we can keep this knowledge in the company now, and new employees can quickly be brought up to date with the product range.

Benjamin Bihr

Technical Manager, Beer Grill AG

We produce about 50,000 drawings a year - without customX, this amount would be unthinkable.

Alexander Albig

Senior Manager, SACAC AG

In addition to SAP, customX has become a strategic element for us.

Heinrich Kriesi

Product Manager Systems, Meier Tobler AG

Over the last 10 years our software has been continuously developed. Today, even some of our suppliers are involved. customX has become an integral part of our daily business.

Gilbert Lux

CEO, unitec Energietechnik GmbH

We felt we were in good hands at all times. We expect a significant increase in the efficiency and speed of the constructive processes with the new configurator.

Benjamin Ganser

Plant Manager, Günther Zierath GmbH

With customX we have software that helps us to configure our products quickly, clearly and customer-specifically.

Schroeder Valves GmbH & Co. KG

The cooperation was excellent.

Franz Meyer

Junior Manager, Peter Meyer @ Co. AG