Bals Elektrotechnik GmbH & CO. KG

Configuration software works efficiently for individual power distributors.

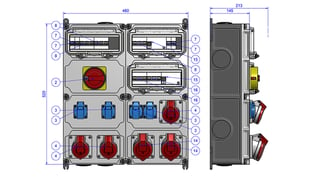

Bals Elektrotechnik GmbH & Co. KG is an independent, medium-sized family-owned company in North Rhine-Westphalia which produces electrical plugs and sockets in accordance to IEC 60309 1-2 as well as plugs and power distributors in accordance to DIN EN 61439 for global markets. The company's success is due to its flexibility, customer focus and fast reaction to short-term requirements. To achieve this, Bals relies on the configuration system customX from Man and Machine. This software handles mechanical as well as electrical engineering in the same system and ensures the fast and error-free production of individual power distribution boxes.

Targets

To link sales, project planning, work preparation and production, whereby mechanics and electronics should be combined in one system. To provide an interface to SAP® with automatic data exchange, and to automatically generate production drawings and customer documentation.

Implementation

Together with our experts, the knowledge about the product was systematically recorded in the customX rulebook. After the implementation of the configurator, the project planning department now creates the product variants and generates all required documents at the push of a button. customX exchanges data with the ERP system via the interface. The rulebook is maintained internally at Bals.

Conclusion

Die internen Abläufe wurden grundlegend verändert und größtenteils automatisiert, was alle Beteiligten deutlich entlastet. Die Zufriedenheit drückt sich darin aus, dass Bals nun plant, das Konfigurationssystem auf weitere Produktbereiche auszudehnen.

Always a perfect connection

Configure electrical & mechanical components in one system. customX enables fast, error-free production of individual power distributors.

Individuality necessitates a wide variety

Especially in the area of distributors, customer requirements differ extremely, which has to be kept in mind during configuration and production. This results in a big number of variants and occasionally even results in the production of individual items for single customers. “This variety of different power distributors is a big challenge for sales, planning, work scheduling and, last but not least, production. General weaknesses caused by communication interfaces in the process were eliminated by customX“, says Heiko Germershausen, project manager at Bals. "Right from the start, in the quotation phase, all necessary data and documents are available for all the different departments.“

Easy handling of variants

One of the biggest challenges was to find a software system that could be used for mechanical as well as electrical parts. The initial idea was to use Autodesk Inventor, as it generates material master data and bills of material via an interface to the ERP system. But this was rejected because: “Even in this early phase we recognized the advantages of a configuration system”, says Heiko Germershausen. Thanks to its high-performance rulebook, all product details as well as the whole relationship knowledge can be mapped in the system – further there is no need to train all the users how to use a CAD system.

Bals quickly decided to implement customX, a configuration system that is connected to SAP ERP HANA by a standard interface. Together with configuration experts, the whole product know-how as well as the relationship knowledge was digitalized in the customX Rulebook. By implementing this innovative software, all users at Bals have internalized a way of thinking according to product systematology – always supported by the experts from customX. The product is now completely described by rules and is no longer dependent on the special product know-how in the heads of the employees.

Today, the project planning department creates the configuration in the software tool, which automatically generates all constructive data, drawings and texts. All this data is automatically transferred to the ERP system, which for its part generates the calculation and the whole quotation. The whole process from the entry of customer requirements to production preparation is automatized and only takes a few seconds. With customX, Bals has found a solution that meets all its requirements concerning product systematology, process reliability, process speed and documentation. For example, technical documents, construction drawings, wiring diagrams, bills of material, working plans, calculations and production documents are generated completely automatically at the push of a button.

Process in the background

In the background, lots of calculations run automatically. When the housing size and the requirements are chosen, customX calculates personal protection, line protection, clamps, cable lengths etc., as well as the position of drill holes in cover and housing – all of these are operations that were previously done mostly manually and were based on the specific know-how of the users. This know-how is now recorded in the system, which is maintained by specialists at Bals themselves, who continuously adapt the rulebook to new product developments. Thus, waiting for an external service provider is no longer necessary and the product know-how stays inside the company.

Quick and safe

The system creates all Inventor drawings in two views, 3D models, 3D PDF and the complete customer documentation, and then transfers this data to SAP ERP HANA for the automatic generation of the calculation, bills of material, parts master data, classification, etc. As the calculation is now based on a quantity structure, it is 100% correct. After the customer has placed his order, production can start immediately as all documents have already been created. The internal process from the order intake up to production is now significantly faster.

In the future

With the implementation of the configuration software, internal processes at Bals changed fundamentally. As a result, employees have significantly less stress, which leads to high-level satisfaction. “Faster, reliable and safe: customX is the right product for Bals”, Heiko Germershausen makes clear. In the future, Bals plans to use the configuration system for further product lines.

With customX we use a professional system which allows fast, complete and error-free configuration of variant.

Heiko Germershausen

Technical Sales, Bals Elektrotechnik GmbH & Co. KG