Trench Germany GmbH

Mechanics and electronics of transformers are configured and calculated in the same platform, with customX as the central point communicating with other customX components as well as with third-party software.

Targets

The basic objective is to avoid multiple entry of requirements and technical data and thus reduce the error rate. The software used must be compatible with both AutoCAD and Inventor and meet the requirements for mechatronic variant design.

Implementation

The standard software customX was introduced, with Trench building the control system itself with the support of customX. For the specific electrotechnical calculations, a separate program was created with the help of customX, which is closely linked to the standard software and automatically supplies data to it.

Conclusion

Due to the process being mostly automated, the error rate has dropped significantly. At the same time, this also increases the speed of the process. By acquiring all product knowledge in the rule set, data is neatly presented, and product adjustments can be easily made.

Automatic Accurate Design of Mechatronic Variants

Electricity is one of the most important resources for today's society - the abandonment of fossil fuels makes it even more significant. Voltages and currents have to be controlled in huge substations. To ensure this process without risk, grid and power plant operators around the world need instrument transformers from Trench - each of them is unique. Nowadays, the standard software from customX, together with the individual calculation program, takes over the automatic configuration and design of electrotechnical and mechanical components to speed up the process and avoid errors.

Unique Products of Best Quality

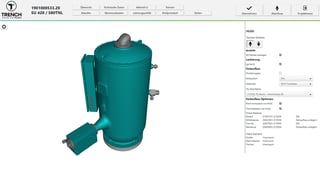

The Trench Germany GmbH, headquartered in Bamberg, supplies instrument transformers to grid and power plant operators all over the world, with each of the 1500 annual order items specified and manufactured to customer specifications. Every detail matters since instrument transformers are operated in a system-relevant infrastructure. They are technically highly sophisticated devices where exact manufacture and function are essential. The challenge is the precise transformation of the voltage and current in high-voltage lines to a lower level. This is then used for measurement and control purposes in the substation control rooms.

The core of the transducer is formed by transformer windings inside, which are responsible for an exact translation of the electrical values. These high-voltage components are arranged in a pressure resistant enclosure and electrically insulated by a gas. This places high requirements on the quality and assembly of the components and materials used.

High Requirements Lead to cutsomX

Therefore, electrical engineering calculations, mechanical components and geometries must be taken into account in design and production. For Trench, this used to mean an enormous amount of work, since the data had to be entered several times at many different points by different people or departments - in the engineering department, for the electrotechnical design, for the creation of the power rating plates, etc. In addition to a considerable expenditure of time, this procedure led to a high susceptibility to errors. The creation of parts lists also proved to be very time-consuming.

This initially gave rise to the idea of using a configurator that would eliminate the need for multiple manual entries. A quick web search led to customX, a subsidiary of Man and Machine. The software platform was particularly convincing in that it is compatible with both AutoCAD and Inventor - both programs that have been in use at Trench for a long time. The requirements for a mechatronic application could be met as well.

Responsible for the introduction and maintenance of customX is Stephan Naetscher, who works as an Industrial Engineer in Operational Excellence and, in addition to customX, is responsible for equipment design and hall planning as well as being involved in lean management.

Fast Step by Step Implementation

First the entire product knowledge had to be transferred into rules that are based on Excel language. Trench was able to build its rulebook largely on its own with the support of customX's project engineers, pleasing Stephan Naetscher. As he describes, he loves the logic challenge of describing the product in rules. So, he and another colleague quickly completed the rulebook and put it through its paces. Afterwards more users were added, and the system was used productively. Mr. Naetscher considers this approach to be optimal because problems can be quickly identified and corrected during step-by-step elaboration.

For the electrical design, customX developed a new calculation program in close cooperation with Trench's specialists based on an outdated predecessor and integrated it into customX so that both parts - configuration and calculation - now go hand in hand. The linking to SAP and the related data exchange are established.

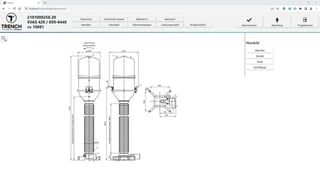

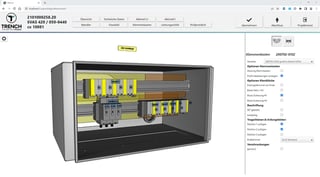

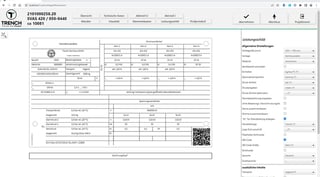

Complete Mechatronic Application

Nowadays, the customer directly sends their requirements and specifications such as voltage and transmission ratio directly to Trench. The technical data - electrical requirements, desired attachments and fixtures, color structures, desired languages for the documents/signs, etc. - are entered directly in customX by the mechanical order processing department. In a second step the mechanical order processing department optimizes the winding data of the transformer components regarding their technical parameters and costs with the help of the integrated calculation program. As a result of the inputs, customX now automatically generates all documents such as dimensional drawings - for rating plates, terminal box, and the instrument transformer itself - SAP parts lists and production documents such as winding instructions and assembly instructions. The ample test documents for testing each individual product are generated automatically after production. Among other things, data such as header data and serial numbers are transferred from SAP, which in turn are used for the rating plates.

In total, customX automatically generates approx. 6000 highly specific documents per year.

The entire process runs automatically, although manual intervention is possible at any time.

Broad Product Knowledge

In addition to the intended effects of significant process acceleration and a significant reduction in the error rate, Trench also appreciates the other effects. The entire product knowledge is summarized centrally in a database. The knowledge database facilitates finding individual components and making minor corrections to the product.

customX is our knowledge database in which the complete product know-how is recorded. The easy retrieval of data makes maintenance and expansion of the system very simple.

Stephan Naetscher

Industrial Engineer - Operational Excellence, Trench Germany GmbH

What the Future Holds

Stephan Naetscher has a clear vision of what the future holds for customX at Trench. He plans a more intensive connection of the quotation system so that quotations can be created directly by the sales department without further internal consultation. The idea is an intuitive traffic light system that, after a simplified input, directly signals what is technically feasible and where additional consultation with the technical department is required. This should make the offers available even faster, and thus also the detailed documents.

Furthermore, an extension to other products in the Trench portfolio is planned.

Perfect Match

The wide process coverage and the complete capture of product knowledge in both the electrical and mechanical areas bring great advantages for Trench due to the low error rate as well as the high speed of the processes. Through the additional programming of the specific, electrotechnical calculation program carried out by customX, the application is perfectly adapted to the mechatronic requirements by Trench, so that even complex processes and calculations are automated and thus maximally simplified.