Reflex Winkelmann GmbH

With customX, Reflex achieves a high degree of automation, enormous time savings and an end-to-end process with 100% CAD automation.

.

Reflex Winkelmann GmbH in Ahlen (Westphalia) is part of the Winkelmann Group, which employs over 4,000 people worldwide and is divided into various business units. One of these is Winkelmann Building&Industry (WBI), to which Reflex Winkelmann GmbH belongs. Anyone familiar with the heating, ventilation and cooling industry is likely to be familiar with the Reflex brand. As the market-leading manufacturer in the field of pressure expansion vessels, products from this brand are installed in the majority of heating systems.

Targets

In 2017, the then existing configurator was to be replaced, thereby improving the creation of quotations and customer drawings.

Implementation

Initially, the configurator for heating circuit manifolds was implemented on the web to optimize the quotation phase. Gradually, customX included subsequent processes and other product groups.

Conclusion

In addition to the main focus on preparing quotations, the workload of the design department has been greatly relieved by the automation of the drawing production. Processes have been accelerated, waiting times reduced, clarity of quotations ensured and a high degree of automation achieved.

Quick and convenient - digital heating planning

Every heating system is individual

However, there is much more to Reflex brand products than just single components for standard heating or cooling systems, such as those found in single-family homes. For example, Reflex offers individually planned heating and cooling systems for large commercial or industrial systems, which are installed in commercial projects, data centers or district heating systems. Heating circuit manifolds of up to six meters in length per element and a throughput of up to 391 m3/h as well as buffer tanks with a volume of up to 50,000 liters and more are also used in large-scale systems. Both are planned using the ProSinusX planning application, which is supported by customX solutions for configuration and construction.

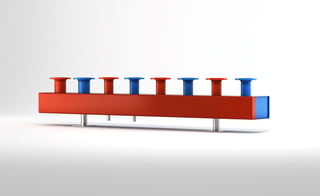

The heating circuit manifolds used in these large systems have a special feature: instead of two manifolds for flow and return, i.e. cold and hot water, Reflex uses just one manifold that combines both. Individual sizes and a varying number of connections as well as variable connection types and mounting options result in an immense variety of product diversity. There is a sine curve between the individual connections which has to be calculated precisely for each individual manifold and differs from manifold to manifold, again depending on the number of connections and the size of the manifold. Calculating this curve requires a very complex process that would take a lot of time to do manually.

Taking it to a new level

Reflex had been using a configurator for some time, but it only delivered rudimentary results. When they became aware of customX, they were quickly convinced that this system could provide customers with real added value and therefore better offers and accurate customer drawings, and so the previous configurator was replaced by customX. And there was another positive side effect. An internally developed system for production drawings could be completely replaced thanks to customX, thus creating unimagined efficiency potential.

Generating all documents automatically

With the previous configurator, Reflex was only able to generate rudimentary drawings. The exact production drawing was then created manually by a designer on the basis of the systemic basic configuration, including prior design checks and any necessary changes. Depending on the configuration, this could take up to half a working day.

Today, the customer configures their manifold directly online with ProSinusX, as the application software is called at Reflex, and can choose between eight different languages. The calculation of the sine curve and thus the design of the manifold take place automatically. Even without registration, every user receives direct visual feedback as well as initial documents, such as supplementary tender texts. For registered users, the system has further data services ready, such as 3D data, PDF drawings or BIM data, and this is provided individually within a maximum of 5-10 minutes. To create the quotation, the data is transferred to a CRM system, prices are saved and the quotation is then sent to the customer at the touch of a button. When the order is placed, it is then processed with ProSinusX, where production documents such as production drawings, material lists and NC data are also generated at the touch of a button after a brief check.

"What wasn't initially intended as such, because we only wanted to replace the old configurator and raise the resulting documents to a new level, is now a 'drastic relief for the designers'," says Christoph Lüning, Application Manager and project responsible at Reflex.

More than 70% of time savings

The figures prove him right: From the inquiry to the start of production, the introduction of ProSinusX has resulted in time savings of more than 70%. Waiting times and handover times are virtually non-existent in this process.

customX drastically simplifies the work of the design engineers and also increases the efficiency of the entire process enormously. Our expectations have been far exceeded.

Christoph Lüning

Application Manager, Reflex Winkelmann GmbH

High usage figures

Other figures also speak for themselves: More than 50,000 projects are currently generated each year. The number of registered users is already well over 10,000, most of them planning offices, engineering companies and installers. The usage figures show a clear upward trend.

To ensure that the configuration system remains stable at all times, even with such a large number of users, server splitting is used, whereby document generation is outsourced to several servers. This means that the dialog server, on which the configuration is operated, can permanently be used for configuration and without any delay.

Individual BIM data

BIM data, i.e. data that planners can use directly in the architecture software, also plays an increasingly important role in the field of heating planning today. Drawings are enriched with additional information and then saved in special formats such as Revit families. This data is already mandatory for public tenders, but is generally increasingly in demand, especially for large-scale projects such as those supplied by Reflex. It is, therefore, not surprising that BIM data is already created for 17% of all configurations. Here too, Lüning is observing a clear upward trend.

Step by step at full speed

Reflex proceeded step by step when introducing the new software. This was the case for both the usage by individual departments and for the expansion to include more and more products. The range now comprises eleven product groups from the heating circuit manifold and buffer tanks areas.

In the end, an end-to-end process has been created for these products without media disruptions and with complete CAD automation in the area of variant design.

Enthusiasm throughout the company

Everyone at Reflex - the internal project managers, the external sales colleagues in consulting and the customers - are more than satisfied with this software. The expectations for the result and the performance of the software have been far exceeded.

And why is that? There are numerous reasons for this - individually they would already provide significant improvements, but in their entirety they completely convince everyone. For customers, an enormous increase in convenience and efficiency is the top priority - they receive detailed documents quickly and easily and also benefit from a shorter overall process through to product availability.

Of course, Reflex also benefits from the increased efficiency - the preparation of quotations has been simplified, the workload of the design engineers has been greatly reduced, processes have been streamlined and accelerated and, above all, digital consistency has been achieved throughout the entire process. The avoidance of errors through the automation of processes also plays a major role. The additional avoidance of waiting times means that significantly more orders can be processed, resulting in higher quality and quantity.

Involved right from the development phase

ProSinusX also plays an important role in future product development: Right from the development phase, the feasibility of implementing innovations in the configurator is repeatedly checked. ProSinusX is also an important source of information on customer requirements, which are then incorporated into developments. This results in valuable synergy effects between development and the product configurator.